Sewer raft

Underground City Oy

2025

Our team designed and produced a raft which is used to document condition of sewer pipe systems. The prototype is made by heat forming 3mm PE-300 plastic into a shape. Raft has a watertight chamber for electronics and four cables to assist with lifting.

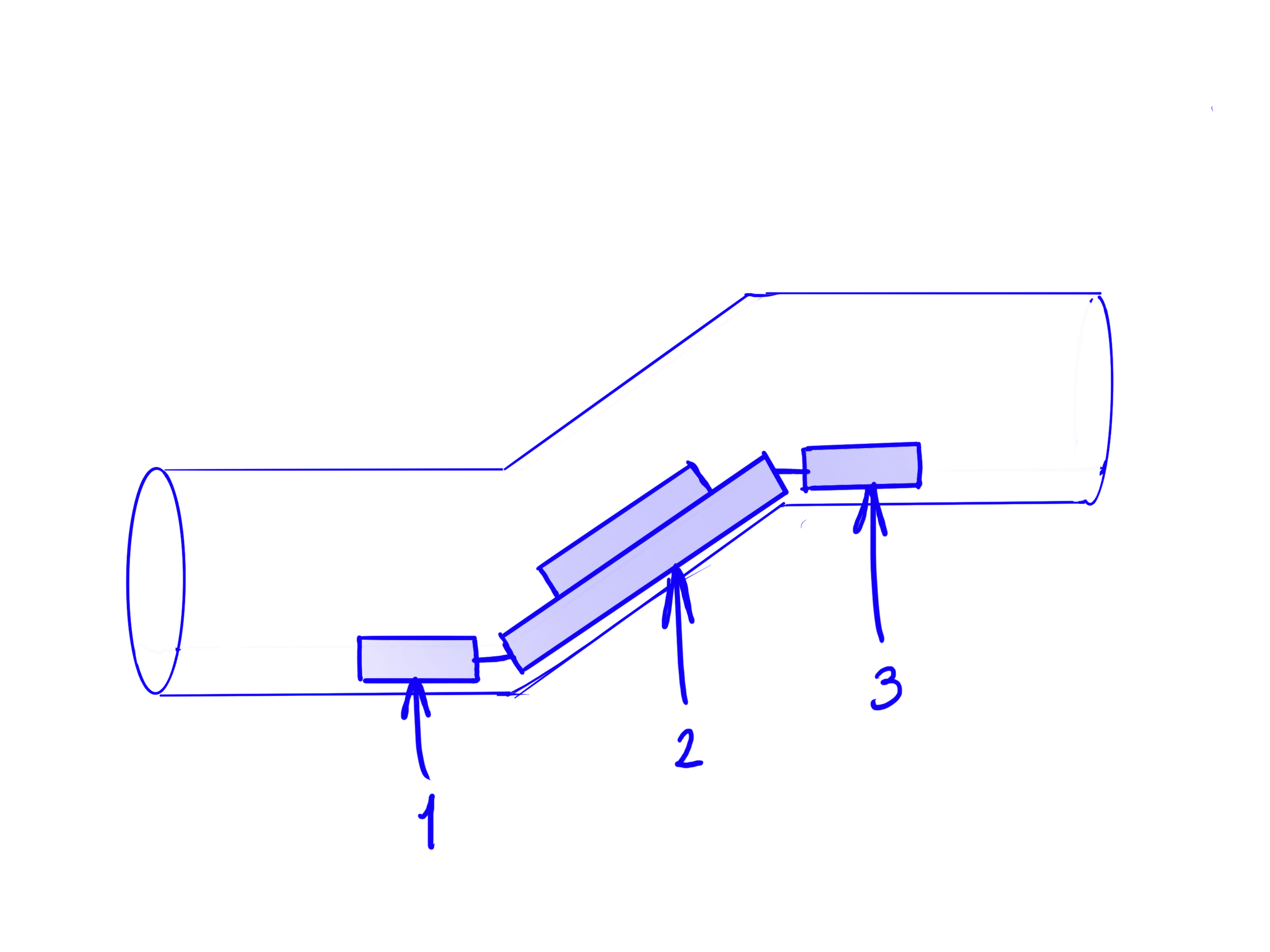

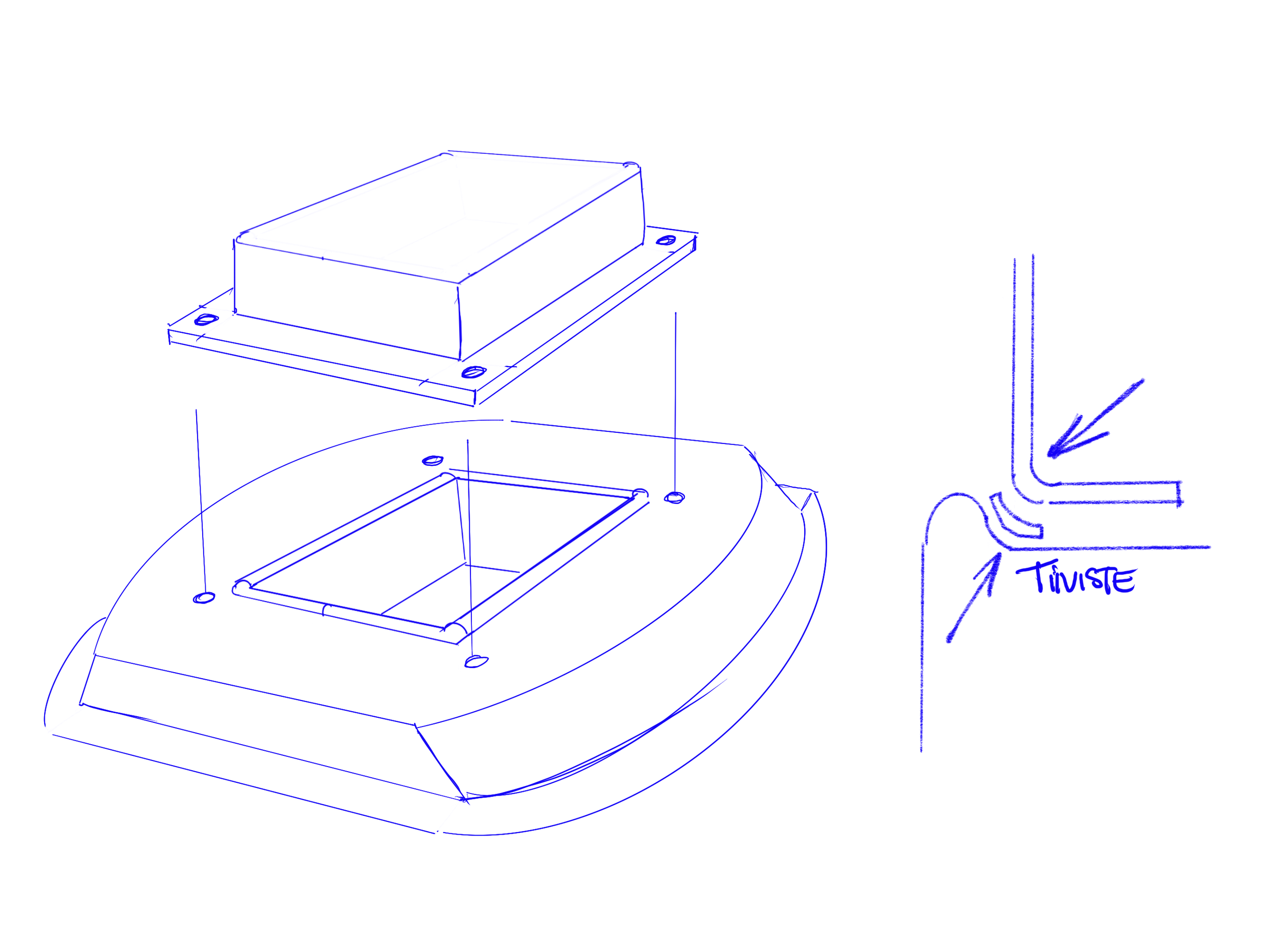

Sketching the prototype. 3-part raft was proved to work in sewer conditions.

Early 3d models helped us to figure out the dimensions between each module. It was a real puzzle because sewer pipes are quite small and raft needs a 2kg battery to operate.

At this point we also researched different materials and manufacturing methods.

We started building the first prototype based on these “final” renderings.

Schedule was so strict that we had time to build only one working prototype. It was clear to us that form follows function and things can change rapidly as we see what truly works.

We decided to use PE-300 plastic because it was moldable, relatively cheap and very strong. Our core idea was to design raft to be extremely durable and easily fixable. It is a tool after all.

Concept visualization of the raft.

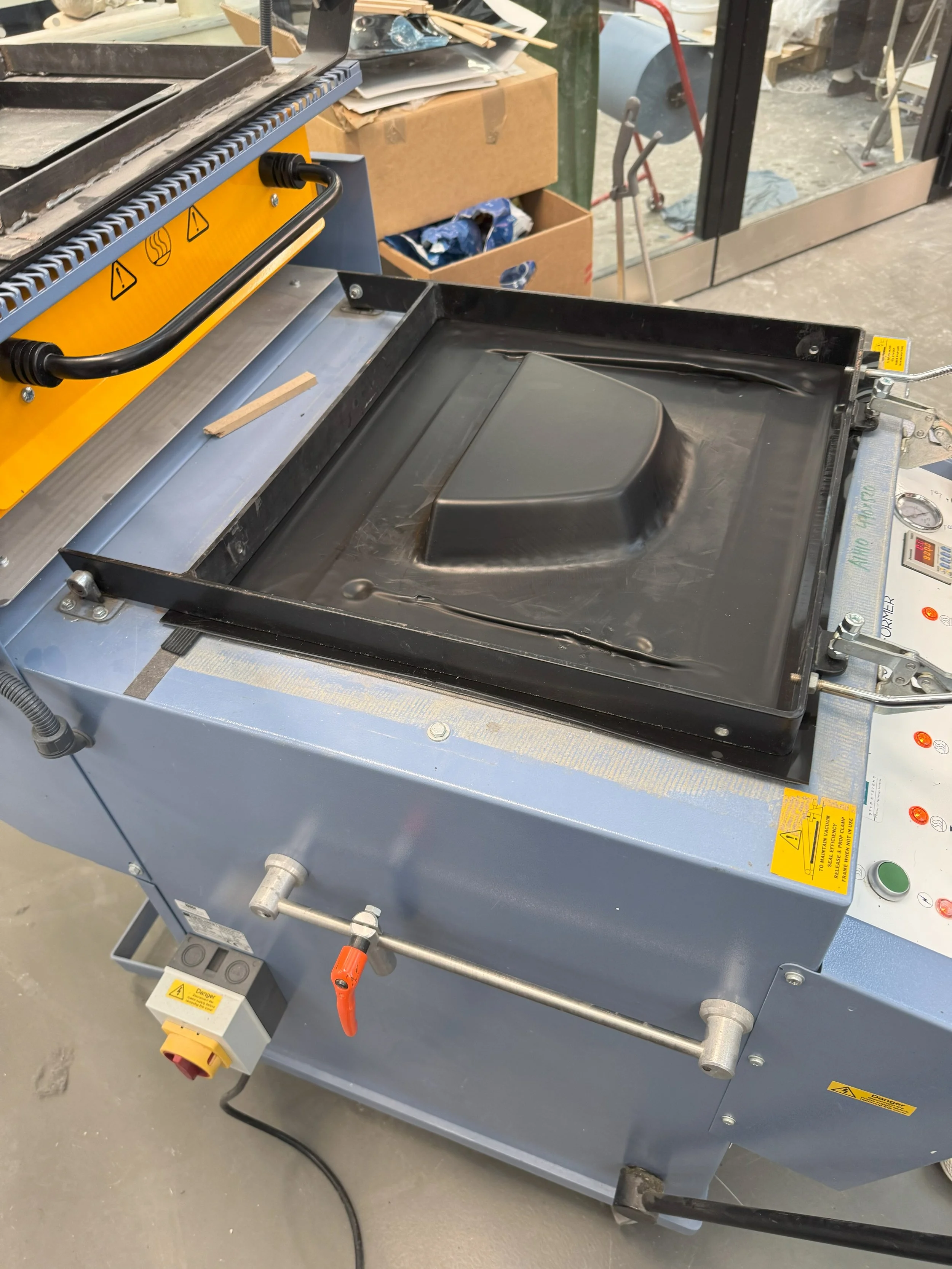

All the separate parts had to be cnc machined out of mdf, because heatforming required positive mold that works with partial vacuum.

Heatforming the bottom of the front module.

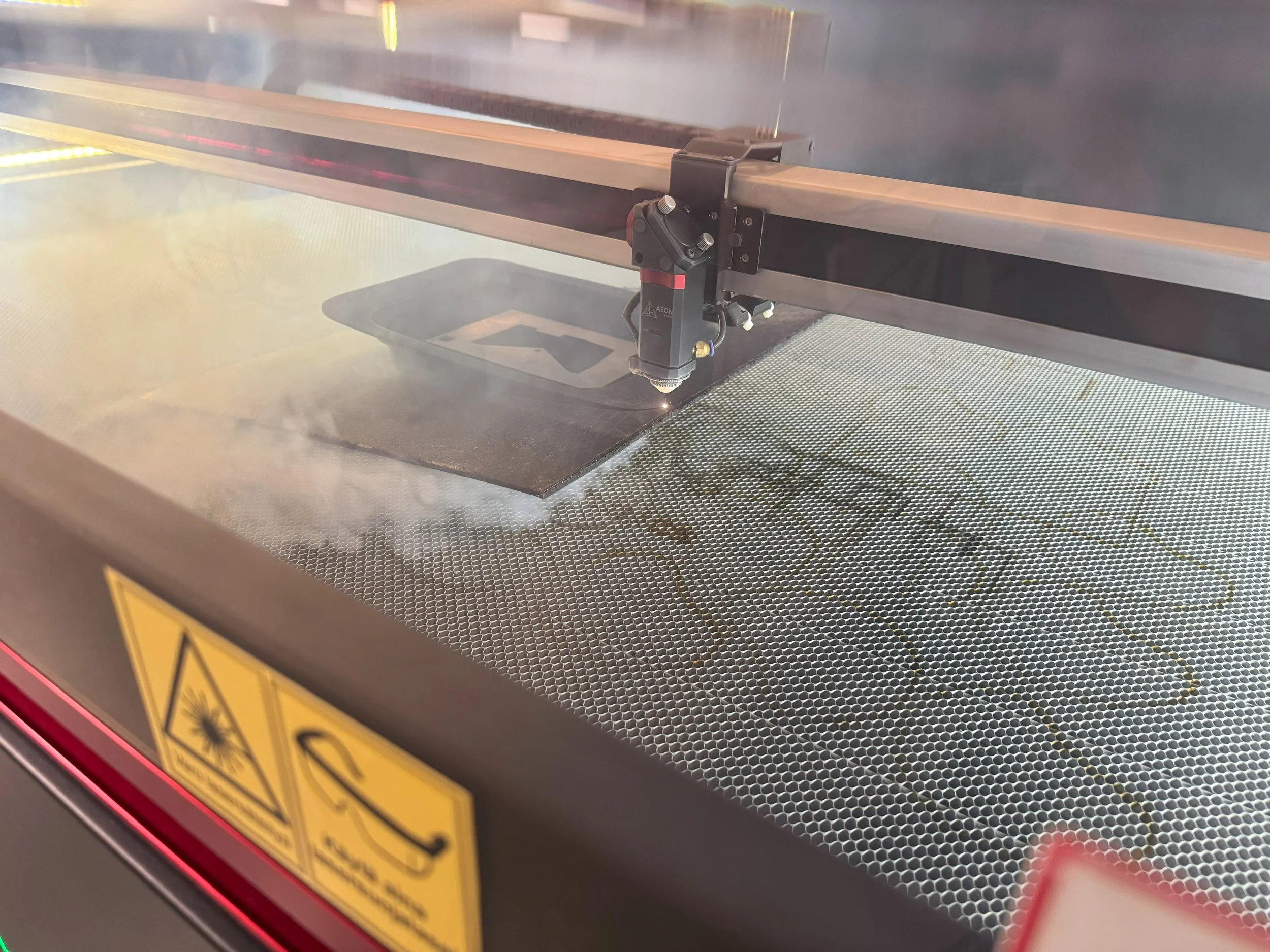

We lasercut parts to the final form.

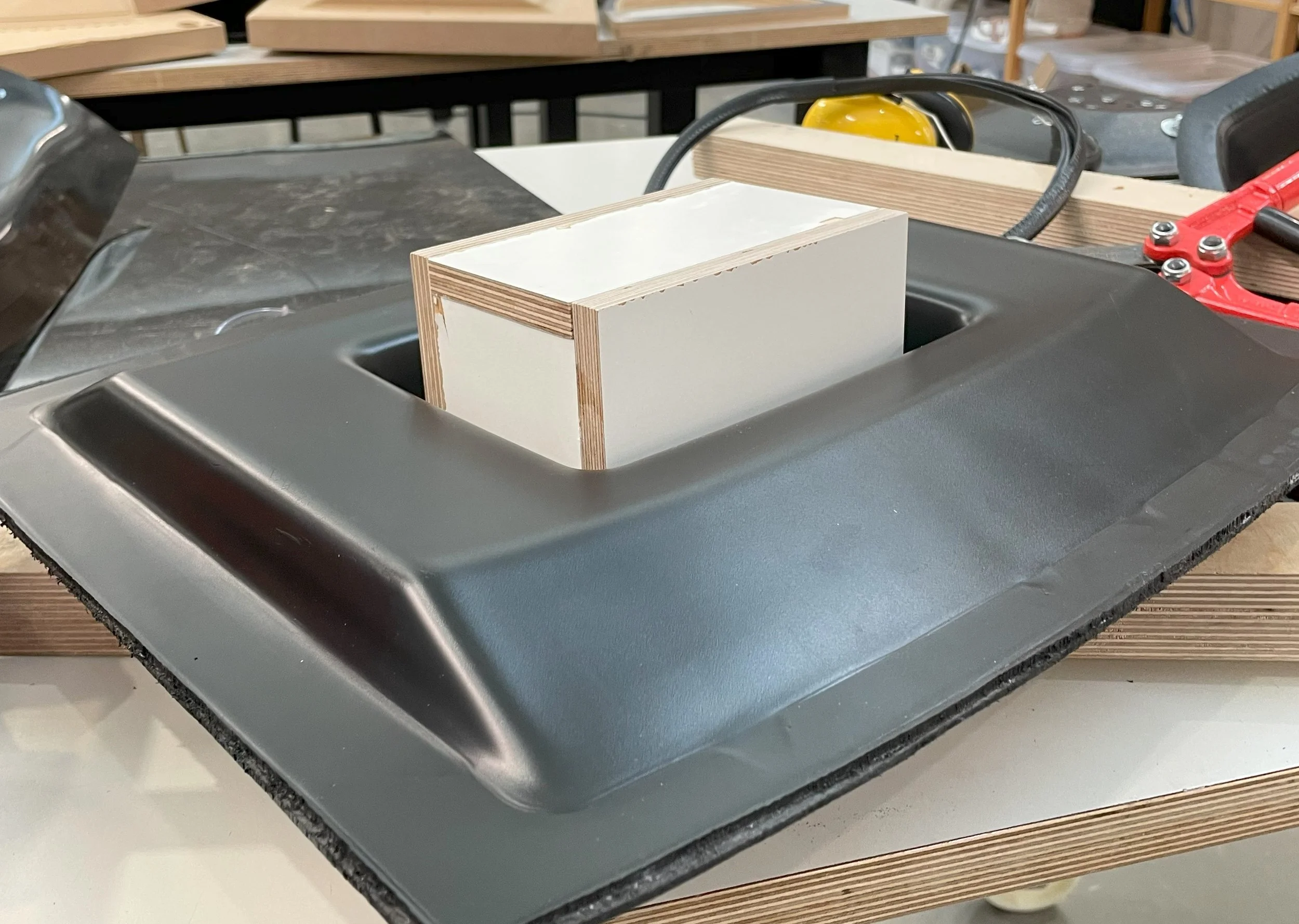

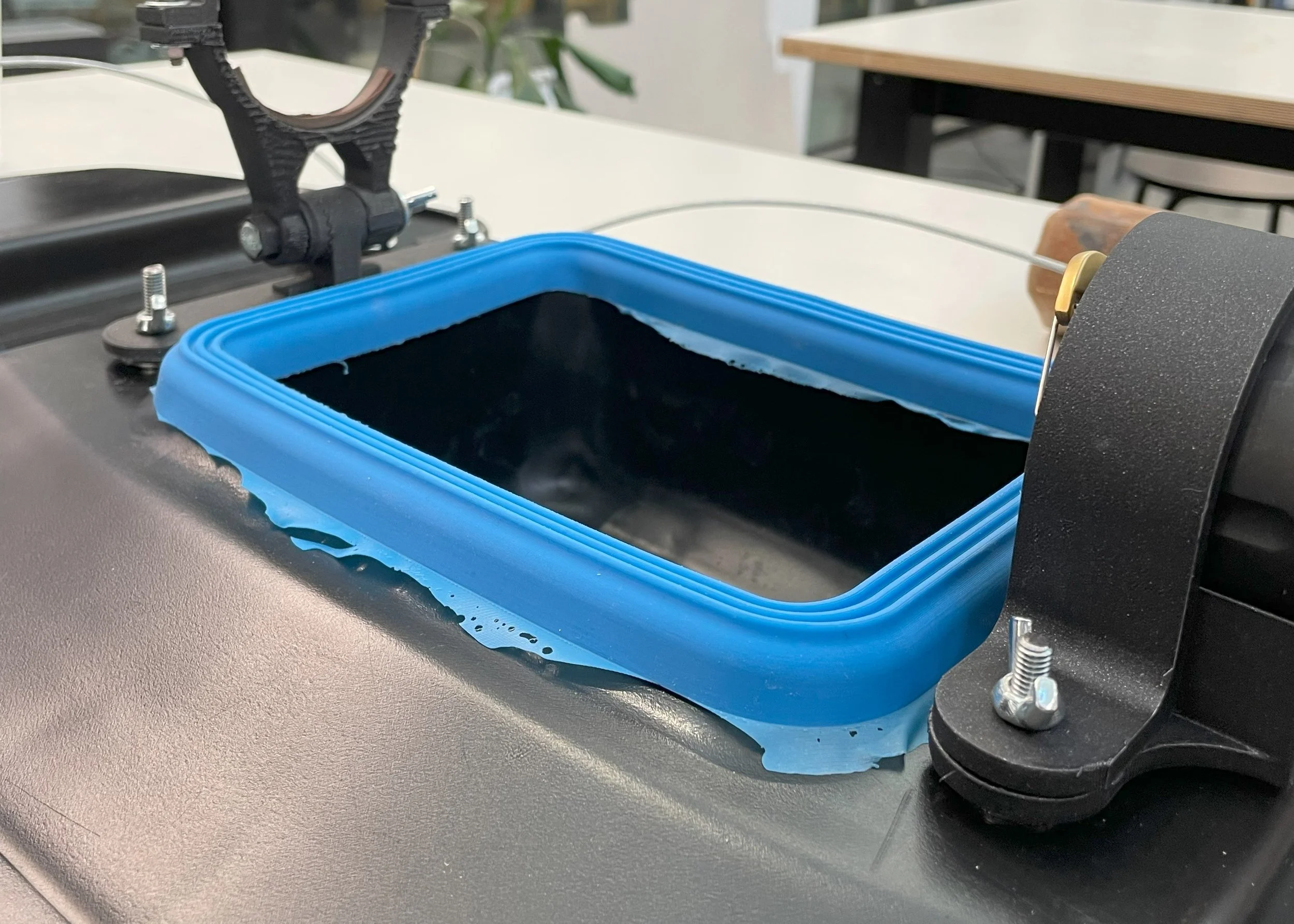

Crucial part of design process was to make the electronics chamber waterproof. It took lots of prototyping to figure the right profile and sealant.

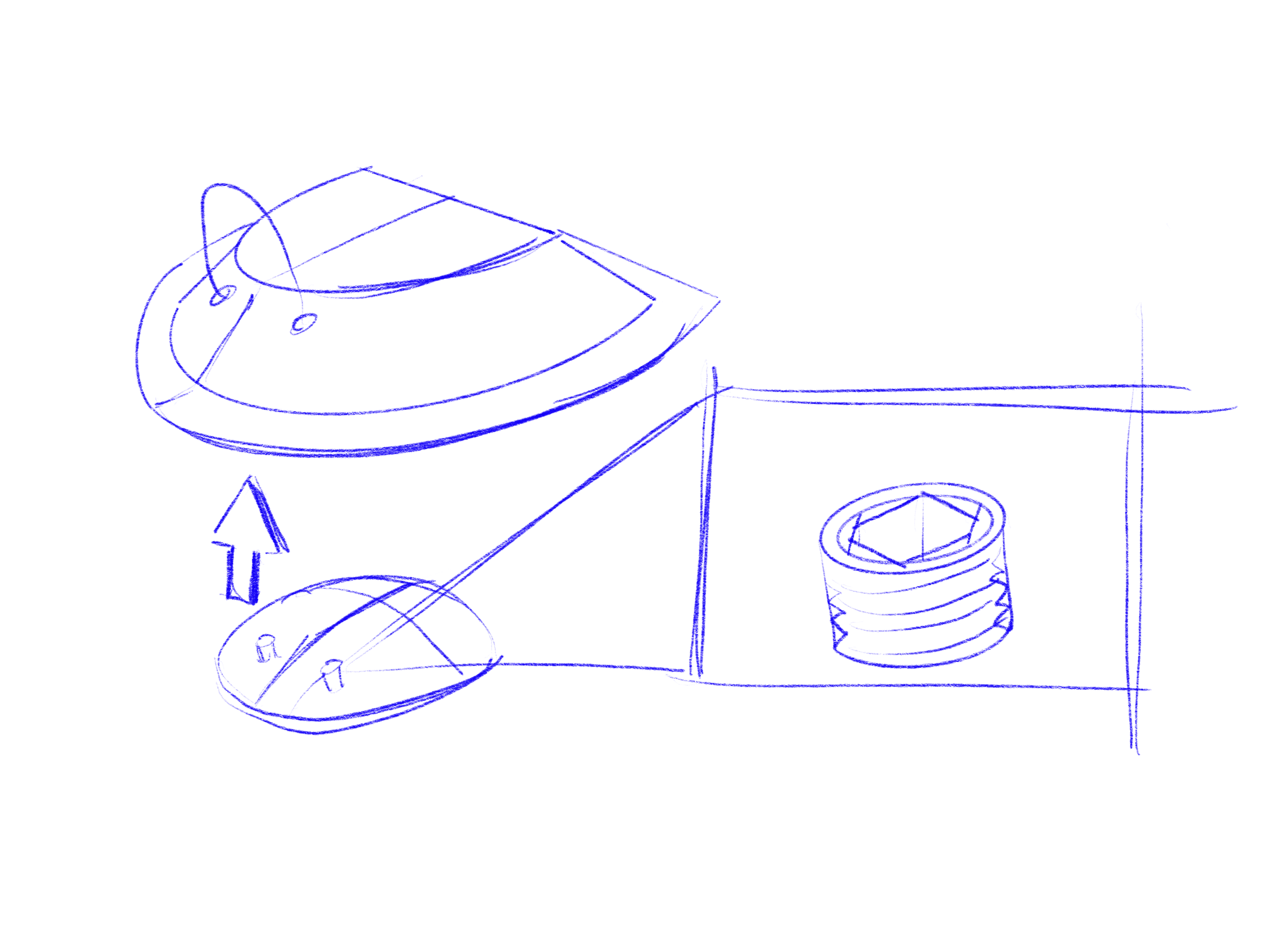

We 3d printed additional profiles to the mdf molds from abs plastic and decided to make our own cast for silicone to seal the lid.

Silicone seal for the lid.

We tested different fastening methods and their durability. Holes in plastic form a risk of water leakage.

Separate parts were clued together. We added cables for lifting and rubbing strips to prevent damage.

Final step was 3d printing mounts for lights with petg.